3 Important Trends to Innovate in Agriculture in 2024

How can you innovate in a traditional sector like agriculture?

Right now, a few critical areas in agriculture are the best candidates for digital innovation.

In this article, we’ll uncover some key trends setting the stage for a more efficient and sustainable future in farming.

Let’s get started.

The three areas that are seeing the most innovation in agriculture

Agriculture is a big, wide world of both traditionalist and modern methodologies.

Some farms thrive by using artisanal processes, some on highly sophisticated technology, and many others fall somewhere in between.

Amazing to think that, at one time, the plow was the pinnacle of technology and engineering. | Source: 12019 on Pixabay

Many operations are hybrid (i.e., some processes are tackled manually or by hand while machines complete others), meaning that not every niche will see the same value in the market’s various products and services.

With that said, a few concepts are (mostly) ubiquitous across the industry, so here, we will look at three areas where the most innovation is currently sought to help agriculture keep pace with the people it feeds.

Optimizing fertilizer production & distribution will have a global impact

One commonality shared by all farmers growing crops is that plants have the same basic needs, with some kind of fertilizer being crucial to virtually all operations.

In addition to water and sunlight, fertilizer ensures access to an abundance of essential nutrients required by plants to meet or exceed size and quality standards.

As such, the nitrogenous fertilizer market is valued near the $300 billion mark and is anticipated to grow at a CAGR of 5.27% through 2027, with phosphorous and potassium markets following closely at just over 3%.

The many methods of applying fertilizer to crops are as interesting as they are important, but we’ll touch on that later. | Source: Mirko Fabian on Pexels

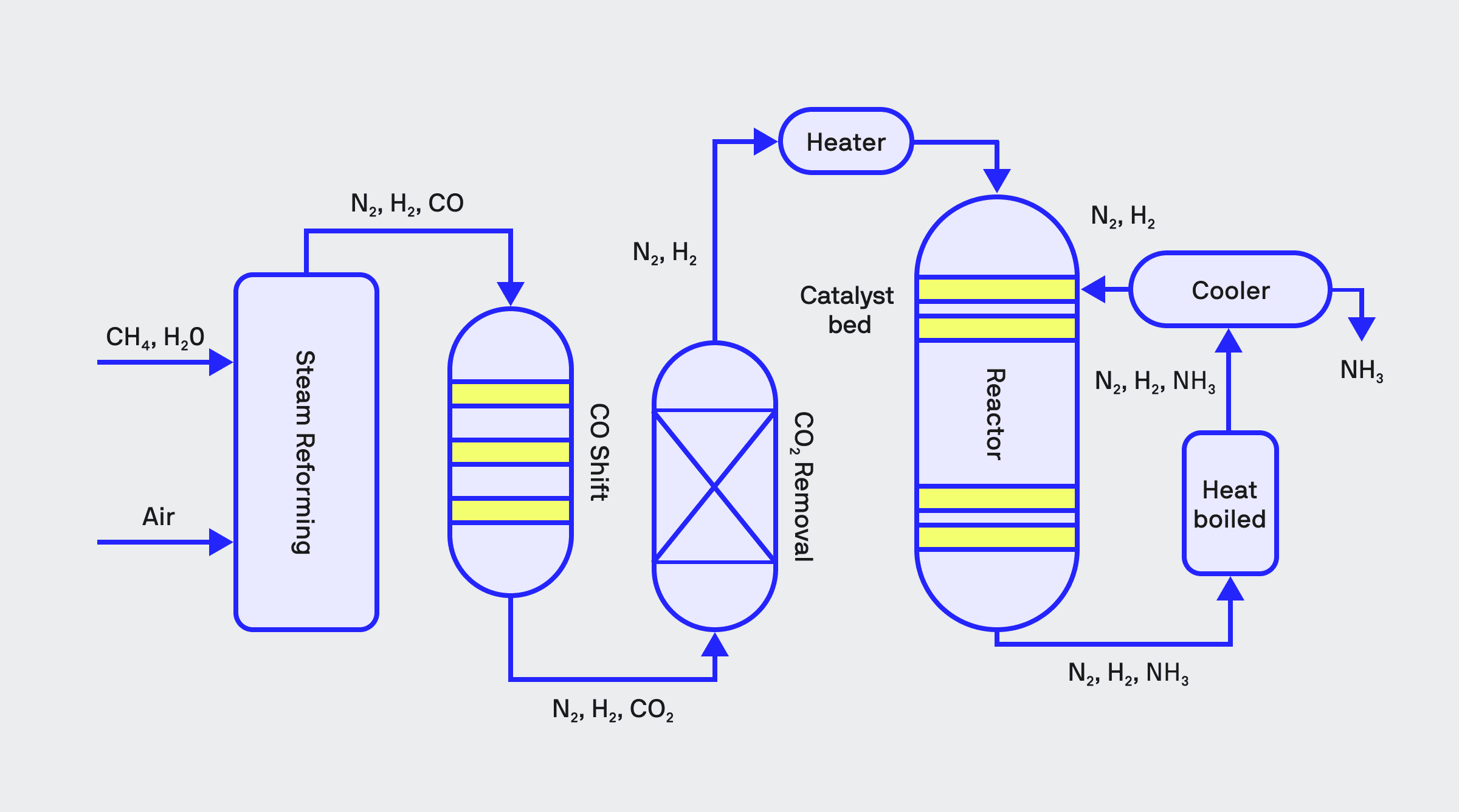

Nitrogen-based fertilizer production relies on the trading and refining of ammonia (NH3) used by inorganic fertilizers.

Without getting into a chemistry lecture, this gas’s composition allows it to be easily liquified and transported or combined with other materials – the compound breaks down once applied to a field through mineralization into different usable minerals and other compounds like nitrogen and ammonium, among several others.

Compared to organic fertilizers, inorganic fertilizers are much more nutrient-dense, producing a significantly higher yield at a much lower cost.

However, a significant amount of precision is required to refine, distribute, and apply these products, which is why software has played an ever-evolving role in the industry over the last several decades.

A simplified diagram of the Haber-Bosch setup used in the industrial production of ammonia.

Software, like commodity management tools and others, has helped drive the production of these chemicals; however, these systems have historically suffered from fragmentation.

Hence, current trends in agricultural innovation have focused on connecting and improving these systems.

Like select other manufacturing processes, the synthesis of ammonia for fertilizer produces byproducts that can be recouped (e.g., unreacted ammonia, nitrogen, hydrogen, etc.) and reused while also creating other byproducts that need to be carefully managed or disposed of.

To bring everything together, agriculture needs fertilizer tech that can:

- Provide and use real-time insights for synthesis processes. The more actual data a manufacturer can access, the better equipped they will be to optimize the use of raw materials and diligently handle all harmful byproducts. Intelligent products help these facilities reduce waste, which is good for profits and environmental compliance.

- Connect all touch points throughout the supply chain. Logistics are paramount to fertilizer production as different products (and the materials used to create them) require a good amount of movement for both the intake of raw materials and the distribution of the final product. By increasing the visibility into certain variables, suppliers can make better decisions based on actual data and avoid missteps in demand planning.

- Improve maintenance management of facility systems. Fertilizer production relies on complex industrial systems, which wear down over time with regular use. Using tools like AI for monitoring processes and production system health helps prevent catastrophes while reporting reaction outcomes in real-time, thus keeping waste and accidents from impacting the environment and the business’s bottom line.

Better software and modern AI can help businesses quickly understand parts of their operation at a glance. With better visibility into the many fertilizer production and distribution processes, companies can make better products with less waste and even get products onto customers’ fields faster.

Better distribution of products & materials means less food waste

One of the complexities related to agriculture is food waste from products expiring before and after it reaches the consumer: every year, approximately 119 billion pounds of food (40% of all food) goes to waste in the US.

On the surface, it seems like an easily solved paradox when overlapped with world hunger: offset food that would otherwise perish, send to the hungry, and voilá: global crisis solved.

Unlike most non-perishable goods, not just any vessel will work when transporting food overseas. | Source: hpgruesen on Pixabay

However, the logistics are complex, like anything else globally.

Since moving most goods requires food-grade logistics (and not just appease a bureaucracy), both for intra and international shipping, there are significant, rapidly shifting challenges to navigate.

Even when we strip away policies and legalities in shipping food, weighty logistic complexities are still required to deliver safe-to-eat, high-quality products to consumers.

Most food products (with some exceptions) do not travel nearly as well as others, especially non-processed foods. And while processed foods (e.g., a box of breakfast cereal, a container of a national brand’s ground coffee, etc.) travel well, a ton of work on the backend goes into packaging and preservation methods.

Cereal has historically been inexpensive, thanks mainly to its portability, allowing some of us to accumulate Seinfield-levels of the product in our homes. | Source: Seinfield on Netflix

Like problems facing the power distribution industry, food products deteriorate while in transit. Unlike the phenomena of losing electricity during transmission, issues with transporting food contain far more variables than what’s required to produce and send energy across the country.

A better grid and distribution of renewable energy sources would nearly eliminate the ~5% of power lost during transmission in the US. However, overhauling the entire road and rail system in the US (an analogous effort to upgrading the US grid concerning power loss issues) would only mitigate a portion of the problem faced in food distribution.

Herein lies one of the most complex issues for agriculture and food retailers: how do you get food that’s going to waste anyway to the mouths of people who need it the most?

Outside of agriculture, organizations like Feeding America partner with the USDA to help get food into public pantries and people’s homes. Other for-profit businesses like Imperfect Foods (that partners with Feeding America) work towards alleviating some of this issue.

However, several other pieces need to come together to truly make a dent in this issue. As such, emerging technologies in shipping logistics, especially those driven by intelligence like AI and ML, can help streamline operations to make shipping much faster.

There’s a lot of room on the market for new solutions in shipping (think Uber but commercial and “food-grade”) as well as some of the less glamorous processes like packaging with computer vision. Ultimately, emerging digital solutions from new and existing providers must be connected and fast, as the clock is always ticking in food distribution.

Some farming robots are available and cost-effective, while others are on track to becoming viable soon.

Advances in AI have made fully automated “farming robots” a reality, like in the example below.

The Autonomous Weeder is one marvel that uses a few different kinds of sophisticated AI to navigate fields while it kills weeds with a laser.

This kind of advancement is truly on the cutting-edge, not just because it’s a robot, but because it combines a few different, appealing ideas into one clever design. It uses solar power as well as various AI and ML functions to navigate and successfully identify problematic plants from crops.

Fruit-picking drones are yet another promising piece of tech that essentially automates what has traditionally been a laborious process.

Though these devices and others are still novel, adoption will serve as a proof of concept and a starting point for companies that build said devices to gather data.

After some time has passed and the industry has collectively accumulated knowledge about these products, new opportunities will present themselves. Eventually, improvements will be reflected in future iterations of these products and in the competition that will naturally arise once demand is established.

We are eager to see other solutions emerge alongside those we’re presently working on – hopefully, we’ll soon see the fruits of our collective labor in industry, both figuratively and literally!